Check Valves - Non Slam..

A check valve, non-return valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, or inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem.

Special Features:

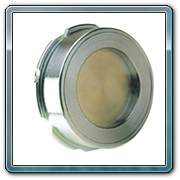

- Is an advanced design which gives full flow and occupy very less space

- Simple to fit between two pipe flanges

- Spring loaded disc to prevent reverse flow in pipe lines

- Compact design of valves flexibly accommodates various types of flange selection

- Valve can mount any direction

- Extremely low operating pressure and self centring type design

Applications

- Process lines

- Downstream pumps

- Heating Installations

- Steam condensate lines

- Compressed air, gases and vacuum lines

- Refineries and storage tanks

Constructional Features

Body

The body is the main pressure containing structure of the valve and the most easily identified as it forms the mass of the valve. It contains all of the valve's internal parts that will come in contact with the substance being controlled by the valve.

Disc

The disc provides a leak proof closure for the valve body. Spring loaded disc is the simplest design, offering a durable, pressure-tight seal.

Yoke

The closure member of the valve, disc is connected to the spring which is up or down to throttle the flow. Yoke is typically of the balanced with the valve body.

Material of Construction:

MATERIAL OF CONSTRUCTION |

||

| Body | : | WCB / SS 304 / SS 316 |

| Disc | : | SS 304 / SS 316 |

| Yoke | : | SS 304 /SS 316 |

| Spring | : | SS 304 /SS 316 |

Technical Specification

Design and Manufacturing Standard

• API 558 – D / BS 7438

Testing Standard

• API 598

Size range

• 15mm to 100mm

Operation

Non slam check valves are opened by the pressure of the fluid and closed by the spring as soon as flow ceases and before reverse flow occurs.