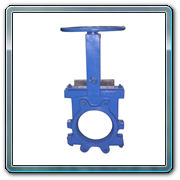

Pulp Valves - Wafer..

We have in store for our clients a wide variety of pulp valves which finds application in several paper and pulp industries for regulating the flow of semi solid material. Furthermore, these are also utilized in other areas like transportation, military, commercial and residential. Offered in various sizes and specifications.

Features:

- Smooth operation

- Less maintenance

- Corrosion and Rust resistant finish

- High tensile strength

- High Efficiency

Constructional Features

Body

Cast Corrosion resistant steel or cast iron to provide receptivity against corrosion For all wetted parts

Disc

The Stainless steel plate is precision-buffed on both sides, to enhance Packing life and ensure positive shut off even heavy or high-viscous fluid.

Seat

Metal-to-Metal, replaceable type for soft seat and other Suitable to application. In addition to standard stainless steel seat ring, rubber ring and Teflon seat rings are Available as options.

Gland Packing

Multi layer gland packing in a variety of materials to suit condition provides total sealing

Stem

Stainless steel having double start thread rising spindle, for fast closing and opening

MATERIAL OF CONSTRUCTION |

||

| Body | : | SS 304 / SS 316 / WCB / CI |

| Disc | : | SS 316 / SS 304 / WCB |

| Soft Seat | : | Metal to metal/EPDM/VITON/TEFLON |

| Actuator | : | Hand Wheel / Pneumatic cylinder / Electrical Actuator |

Technical Specification

Design and Manufacturing Standard

• TAPPI 405

Testing Standard

• TAPPI 405

Size range

• 40mm to 400mm

Operation

• Manual hand Wheel

• Electrical and Pneumatic actuator with accessories & manual override

End Connection

• To Suit ANSI # 125 / 150

Port: Round

APPLICATION

Pulp valves are widely used in various applications such as Cement Industries of Slurry Lines, Pulp & Paper Industries for Stock Lines.