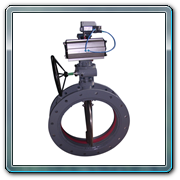

Butterfly Valve - Double Flanged..

Double Flanged type

Widely used in process and general industries, Power, Building and construction, water treatment plant, Sugar and cement industries, Cogen, Vapour and steam applications.

Special Features:

• Top flange drilled to suit ISO 5211

• Bolt circle dimensions to suit all standard Like DIN, ANSI, API, BS 10 Table D&E etc.

• Unique centre stem lock design virtually eliminates any disc movement while during the open / close function

• Unique stem retention system to blow out proof stem easy assembly & Disassembly of valve

Constructional Features:

Body

Heavy Duty Single piece in Fabricated and two piece in castings double flanged body designed to withstand specified pressures & Ratings

Disc

Investment / Fabricated high strength disc with polished disc edges and hubs ensures excellent corrosion resistant to several chemical media

Seat

Moulded seat design – Replaceable (Dove tail for vacuum purpose)

Stem

Two piece stem with close tolerances and also top stem locked with disc of SS Fasteners

Secondary Seal

PTFE Teflon absorbs the force acting on the stem assembly due to line pressure and also act as secondary seal as well as gland seal

Material of Construction:

MATERIAL OF CONSTRUCTION |

||

| Body | : | CI / SS 304 / WCB / Fab. IS 2062 |

| Seat | : | EPDM / NIT / VITON / SILICON |

| Disc | : | SS 316 / SS 304 / WCBI |

| Actuator | : | Gear Box / Pneumatic cylinder / Motorised Actuator |

Technical Specification

Design and Manufacturing Standard

• IS 13095:1991 Double flanged short / API 609 / BS 5155

Testing Standard

• ANSI B 16.5 Class 150Lbs / API 598

Size range

• 300mm to 1200m

Operation

• Manual Gear Box

• Electrical and Pneumatic actuator with accessories & manual override

End Connection

•To Suit ANSI # 150