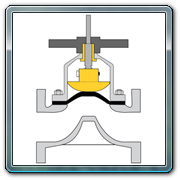

Diaphragm - Flanged End..

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve is constructed from either plastic or metal.

Originally, the diaphragm valve was developed for use in industrial applications. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods.

Special Features:

- Compact Design

- Maintenance free

- Large area mounted actuator diaphragm

- Moving parts concealed

- Cast iron diaphragm housing

Applications

- Water treatment plants

- Fertilizer & Petro chemical plants

- Chemical Industries & Refineries

- Process industries & thermal power stations

Advantages:

- Steady flow

- Tight shut off

- No stem packing

- Easy diaphragm replacement

- Effortless operation

- Less wear & tear

- Better life span

Constructional Features

Body

Valve body is lined with ebonite rubber designed to withstand specified pressures & Ratings

Type

Weir type

Diaphragm

Neoprene rubber moulded plug type diaphragm in which diaphragm isolates the bonnet assembly from the liquid

Bonnet

Bonnet is made of cast iron and grey iron with rigid

Stem

Stem is mounted with diaphragm

Lining

Rubber lining with spark tester as per IS 4682 Part I

MATERIAL OF CONSTRUCTION |

||

| Body | : | CI / DI |

| Diaphragm | : | PTFE with neoprene back up pad / Natural rubber / Viton / EPDM |

| Lining | : | EPDM / Neoprene / Viton / PTFE |

| Actuator | : | Hand Wheel |

Technical Specification

Design and Manufacturing Standard

• BS 5156

Testing Standard

• BS 6755

Size range

• 15mm to 300mm

Operation

• Manual hand Wheel

• Electrical and Pneumatic actuator with accessories & manual override